The Against the Grain Farm family prides itself on a culture that anything is possible. Their members will try anything – at least once. They are not afraid of failure.

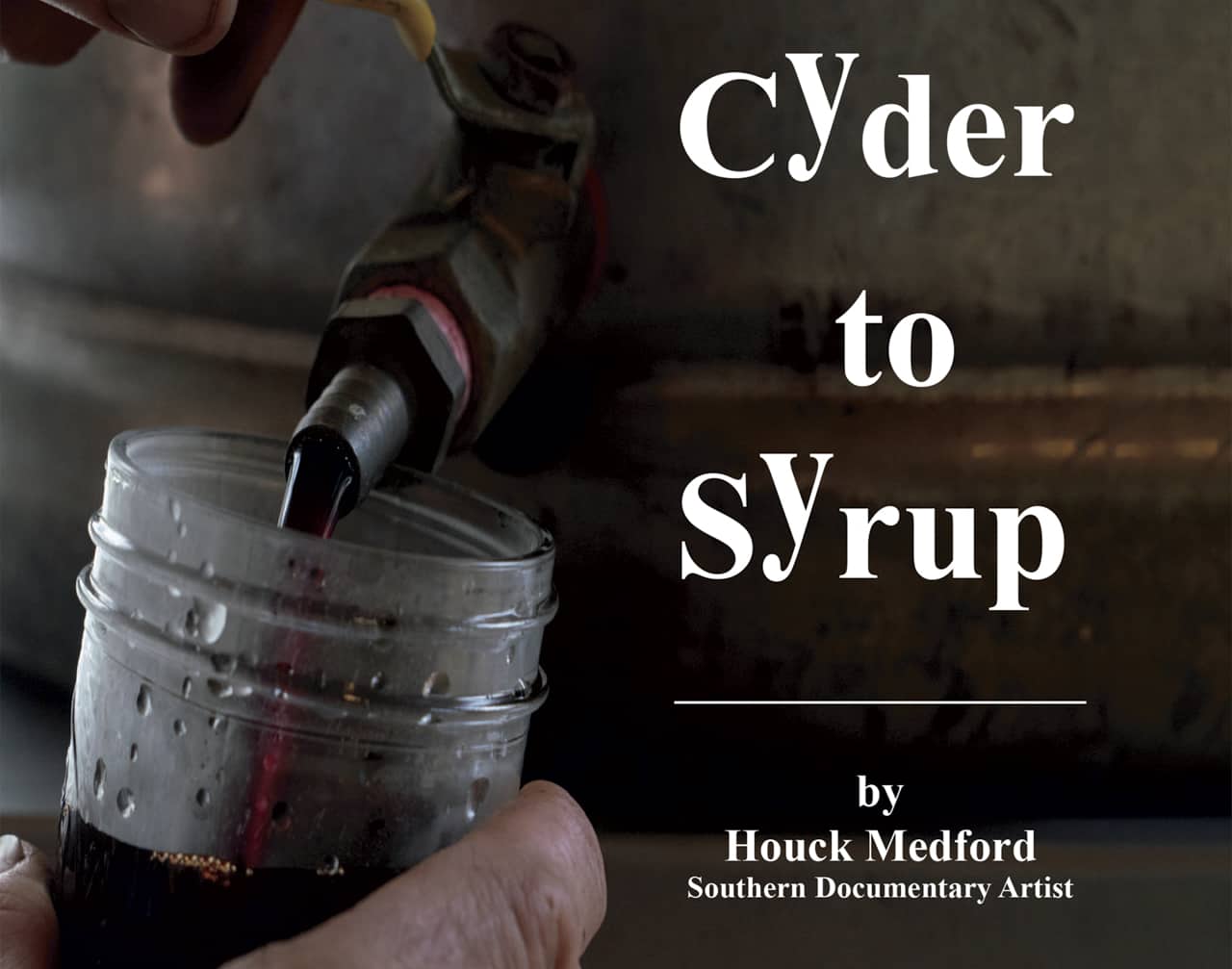

The farm has made molasses before, which is a very similar process. Start with the juice and reduce it with even heat until it thickens.

A test run on the stovetop gave these adventurers all the confidence that they needed.

Full steam ahead! Literally!